Introduction

Introduction

Mechanical systems are the backbone of countless industries, from construction and manufacturing to aerospace and healthcare. They encompass everything from HVAC systems and plumbing networks to intricate machinery and equipment.

But simply installing mechanical systems isn't enough. We need to ensure they operate efficiently, reliably, and safely. That's where commissioning comes into play. Commissioning is the systematic process of verifying that these systems are installed correctly, tested thoroughly, and perform as intended. It's like ensuring all the pieces of a puzzle fit together perfectly before you start the game. Often this is also called Machine Commissioning.

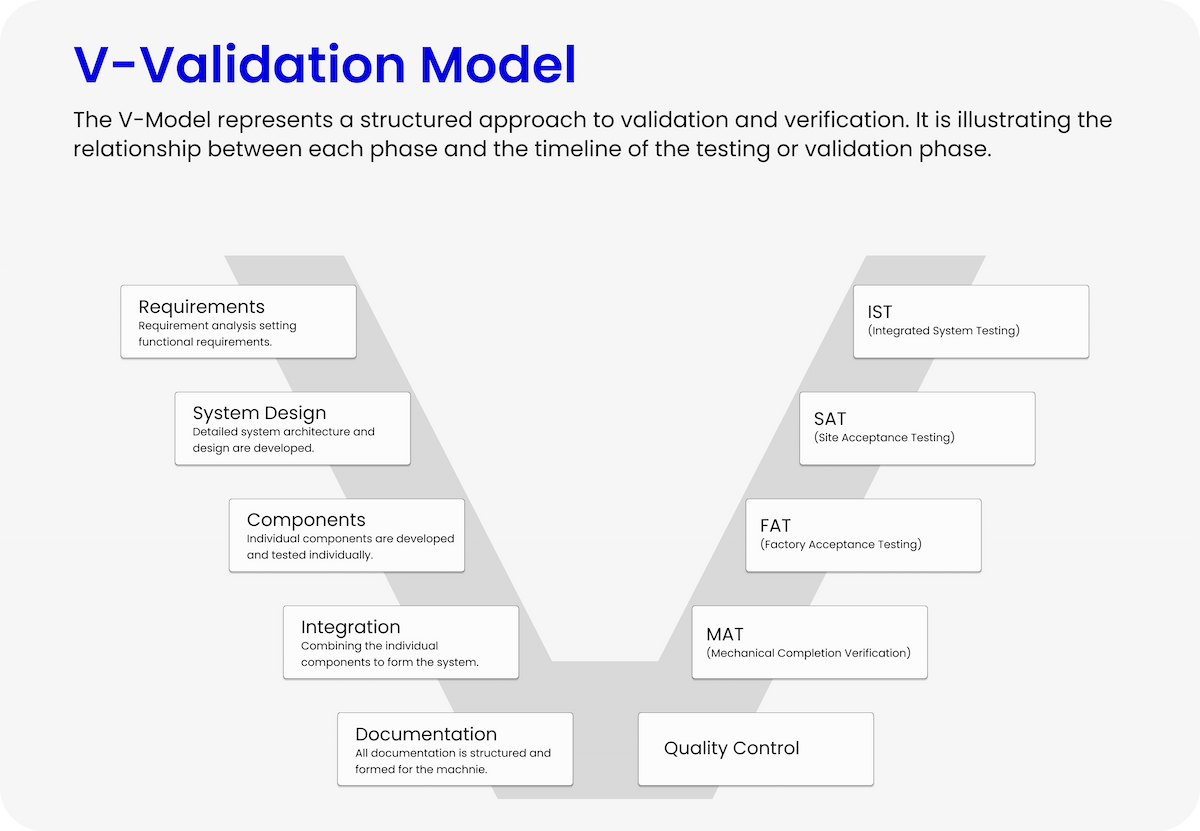

Now, to navigate through this process effectively, we rely on a powerful tool called the V-Validation Model. Picture it as a roadmap guiding us through the journey of system development and verification.

On one side of the "V," we have the project definition phase, where we define requirements, design the system, and develop its components. On the other side, we have the verification phase, where we test, validate, and ensure that the system meets those requirements.

Mechanical Commissioning and the V-Validation model

Mechanical Commissioning and the V-Validation model

What is Mechanical Commissioning

Mechanical commissioning is the systematic process of ensuring that mechanical systems within a building or industrial facility are installed, tested, and operate according to the intended design and specifications. These mechanical systems can include HVAC (Heating, Ventilation, and Air Conditioning), plumbing, fire protection, and other mechanical equipment essential for the functioning of the facility.

The goal of mechanical commissioning is to verify that these systems are installed correctly, function properly, and meet the performance requirements outlined in the project design.

What is the V-Validation Model (V-model)

The V-Validation Model, often referred to simply as the V-Model, is a framework used in the validation and verification of systems or processes, primarily in the context of software development and engineering projects. However, its principles can be applied to various domains, including mechanical systems.

The V-Model represents a structured approach to validation and verification. It is illustrating the relationship between each phase and the timeline of its corresponding testing or validation phase.

The model takes the shape of a "V," with the left side representing the development phases (requirements analysis, design, coding, etc.), and the right side representing the corresponding testing or validation phases (unit testing, integration testing, system testing, etc.). The point at the bottom of the "V" represents the final validation phase where the system is tested against the original requirements.

Combining the two concepts

In summary, mechanical commissioning ensures that mechanical systems are installed and operate correctly, while the V-Validation Model provides a structured approach to validating and verifying these systems, ensuring they meet the specified requirements.

These two concepts intersect when mechanical systems are tested and validated according to the principles outlined in the V-Model, ensuring their reliability, functionality, and compliance.

What industries uses Cx and the V-model?

What industries uses Cx and the V-model?

Mechanical commissioning and the V-Validation Model find application across a range of industries where complex systems need to be installed, tested, and validated to ensure reliability, safety, and compliance.

Building Construction and Facilities Management

In the construction of commercial buildings, hospitals, educational institutions, and other facilities, mechanical systems such as HVAC, plumbing, and fire protection are critical for occupant comfort and safety.

- Example: Before a new office building opens its doors to occupants, mechanical commissioning ensures that the HVAC systems maintain comfortable temperatures, the plumbing systems deliver water reliably, and the fire protection systems operate effectively in case of emergencies.

Pharmaceutical and Biotechnology

In pharmaceutical manufacturing facilities, stringent regulatory requirements necessitate thorough validation of equipment and processes to ensure product quality and compliance with Good Manufacturing Practices (GMP).

- Example: In the production of pharmaceuticals, mechanical systems such as cleanrooms, HVAC systems, and sterilization equipment undergo validation to ensure that manufacturing processes meet regulatory standards and produce safe and effective medications.

Automotive Manufacturing

In automotive manufacturing plants, mechanical systems such as assembly line conveyors, robotic arms, and paint booths must operate efficiently and reliably to ensure production targets are met.

- Example: Before launching a new vehicle model, automotive manufacturers conduct mechanical commissioning to ensure that assembly line equipment operates smoothly, with the V-Validation Model guiding the validation of each manufacturing process to ensure quality and consistency.

Energy and Utilities

In power plants, refineries, and utility infrastructure, mechanical systems such as turbines, pumps, and pipelines are crucial for generating and delivering energy and resources.

- Example: Before bringing a new power plant online, mechanical commissioning verifies the functionality and performance of critical equipment, with the V-Validation Model guiding the testing and validation of control systems to ensure safe and efficient operation.

The left side of the V-Validation Model

The left side of the V-Validation Model

The left side of the V-Validation Model represents the project definition phase, which includes all the activities involved in defining and developing the system or product according to specified requirements. This phase lays the foundation for the subsequent verification activities on the right side of the model.

-

Requirements Analysis:

The initial stage where stakeholders gather and analyze the functional and non-functional requirements of the system or product. These requirements define what the system should do and how it should perform. It involves gathering user needs, business objectives, and technical constraints to define the features -

System Design

The system design phase transforms the requirements into a detailed system architecture and design. This involves defining the structure, interfaces, components, and data flow of the system. This could be specifying the configuration of components such as cylinders, pistons, valves, and fuel injection systems, as well as determining how these components interact to achieve optimal performance and efficiency. -

Component Development

The individual components or modules of the system are designed, developed, and tested independently. E.g. in the construction of a new bridge, component development includes fabricating structural elements such as beams, columns, and girders according to the engineering specifications and standards. -

Integration

This phase involves the integration of the components from the phase above. It involves installing and connection components there must work together, such as the sensors, PLC and SCADA components. -

Documentation

Through all the phases documentation is being generated and updated. This documentation is essential for the validation and the further operation and maintenance phase for the system.

The right side of the V-Validation Model (verification)

The right side of the V-Validation Model (verification)

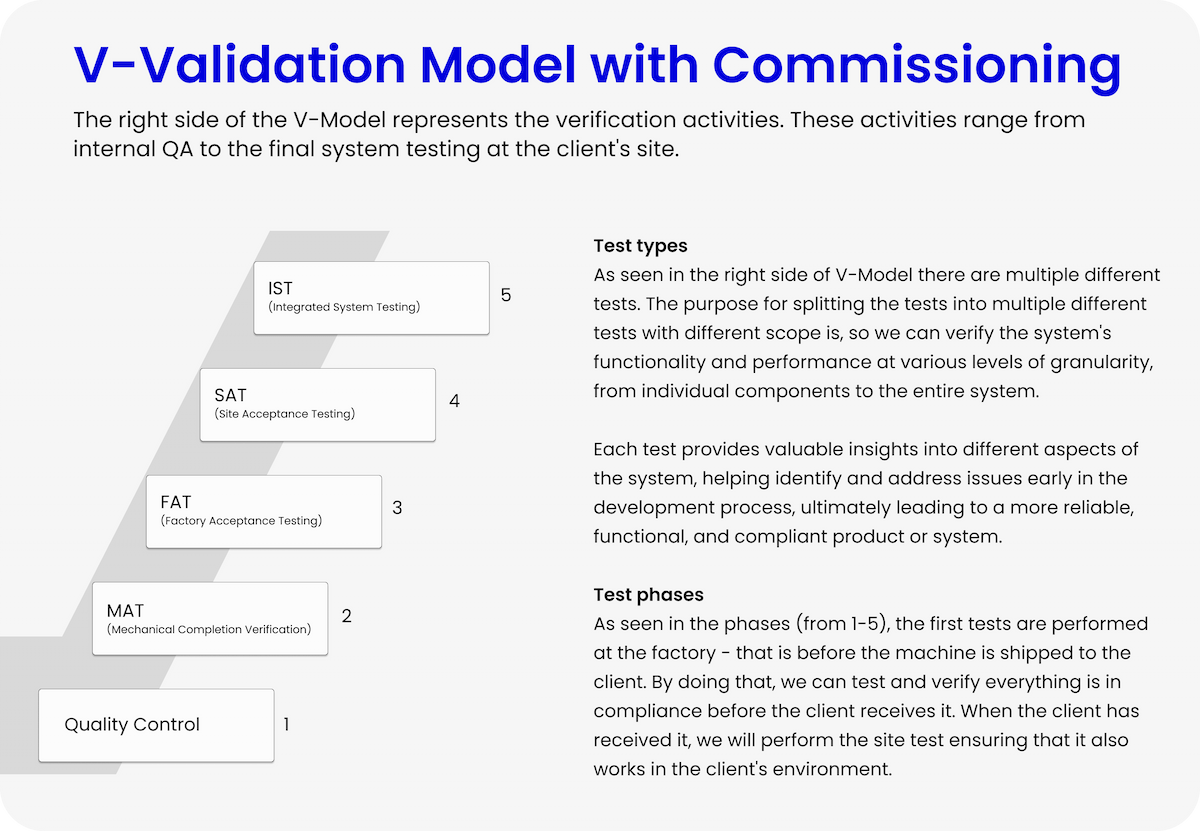

When looking at the right side of the model, we see all the verification activities that are being performed to ensure that the functionality. This includes the verification from simple assembly to the final integrated system testing.

The naming convention of these test-phases will differ between industries, but in the essens they are the same. Like, for many production facilities, they use a methodlogy called MAT (Mechanical Completion Verification) which would be the same as the Unit Testing for others.

CxPlanner has been built to support all kinds of Cx and V-models, so no matter the naming or the structure, you can use CxPlanner to manage the verification.

-

Quality Control

Basic quality control of the components and the assembly is done at the factory. This QA/QC is done to ensure that the components are according to the specs. Normally this does not include functional testing/verification. -

MAT (Mechanical Completion Verification)

The MAT is the first verification of the machine. The main goal for this verification is to ensure quality and approve the machine for power up. -

FAT (Factory Acceptance Testing)

The FAT is the verification of the machine in the factory. Instead of shipping the machine and testing it on site, this is done in the factory. This is done to ensure that the machine can work as intended before shipping. -

SAT (Site Acceptance Testing)

The SAT is the verification of the machine on site. This is done to ensure that the machine can work as intended in the environment it is supposed to work in. -

IST (Integrated System Testing)

The IST is the final verification of the machine (and most fun!). This is were we test, that all components and signals in the full system works as a whole. So an input from a P1000-sensor will give the correct output on the HMI and the PLC, which then will adjust the belt and rotors, etc.

Why use mechanical commissioning and the V-Validation Model?

Why use mechanical commissioning and the V-Validation Model?

Using mechanical commissioning and the V-Model offers a range of direct and indirect benefits, contributing to improved project outcomes, operational efficiency, and compliance

- Improved System Reliability and Performance

- Comply with Regulatories and Legal Requirements

- Reduce quality risks and defects

- Improved client and stakeholder confidence

- Deliver on time and on budget

When taking about the items above, they can often include two (2) groups of benefits: The direct and the indirect benefits. The direct benefits are the ones that are easy to measure and see, like the improved system reliability and performance. The indirect benefits are the ones that are harder to measure, like the improved client and stakeholder confidence.

For many the main driver to implement mechanical commissioning and the V-Model is the cost savings. These savings can often be significant and can be the difference between a project being profitable or not. The lastest research thesis showed that going from Excel spreadsheets to CxPlanner saved the client +50% in time!

Conclusion

Conclusion

By integrating the mechanical commissioning practices and the structured approach of the V-Validation Model offers significant benefits across various industries. Mechanical commissioning ensures that systems are installed and operated correctly, while the V-Model provides a systematic framework for verifying and validating system functionality, reliability, and compliance with requirements.

By implementing a dedicated commissioning and quality management tool, project teams can streamline verification activities, enhance collaboration among stakeholders, and ensure thorough documentation of validation efforts. This not only improves project outcomes and operational efficiency but also enhances stakeholder confidence and compliance with regulatory standards.

In today's complex and dynamic environment, where reliability, safety, and compliance are on the top of the agenda, everyone must be on board. You cannot use legacy Excel and software solutions and think everything just works. You need a dedicated tool that can support you in the process and ensure that you are compliant with the standards and regulations.