Table of content

What is TAB of HVAC systems

What is TAB of HVAC systems

Testing, Adjusting, and Balancing (TAB) is a critical process in the realm of HVAC (Heating, Ventilation, and Air Conditioning) systems. TAB is the systematic and methodical evaluation of these systems to ensure they operate efficiently, effectively, and as designed. The primary goal of TAB is to create a balanced and harmonious environment where indoor air quality, thermal comfort, and energy efficiency are optimized.

The TAB process involves a series of tasks, including measuring and adjusting variables such as air and water flow rates, temperature differentials, and pressure levels. Technicians utilize various instruments and tools to obtain accurate data and then make adjustments to HVAC system components like dampers, valves, and fans. The objective is to align the system's performance with the design specifications and intended functionality

Proper TAB provides several benefits, including reduced energy consumption, enhanced occupant comfort, and prolonged equipment life. Additionally, TAB is integral to commissioning, which is the thorough evaluation and testing of HVAC systems during construction or retrofit projects.

In summary, TAB is a meticulous and essential procedure that ensures HVAC systems perform optimally, delivering the desired indoor environment while minimizing energy usage and operational costs. It plays a pivotal role in the broader context of system commissioning, making it a cornerstone of the HVAC industry.

Main challenges with performing TAB

Main challenges with performing TAB

Not everyone can perform TAB. Firstly, HVAC systems are complex and interconnected, comprising a multitude of components such as fans, ducts, dampers, valves, and sensors. Achieving a harmonious balance among these components is intricate and demanding.

Secondly, the diversity of HVAC system types, ranging from constant air volume (CAV) to variable air volume (VAV) systems, each with its own unique design and performance requirements, adds complexity. Technicians must possess in-depth knowledge of various system configurations and their corresponding intricacies.

TAB-works can have critical impact, imagine performing TAB on the HVAC systems during a commissioning process of a data center. If your TAB is wrong that could leed to overheating of the servers and a complete shutdown of the data center. This could cost the company millions of dollars in lost revenue.

How to Perform TAB on Site

How to Perform TAB on Site

Traditionally, TAB involved manual data collection and documentation using spreadsheets and paper forms. Technicians would take measurements on-site, record them, and then perform time-consuming calculations manually. This process was not only prone to errors but also resulted in a significant amount of post-processing work.

Modernizing TAB on-site involves using digital tools like CxPlanner, which streamline the process. Technicians can input data directly into the platform, making real-time adjustments and ensuring that the HVAC system is functioning optimally. This not only saves time but also significantly reduces the chances of errors in the data.

Benefits of Modern TAB:

Modern TAB solutions like CxPlanner offer a range of advantages:

- No More Post-Processing: With automatic calculations and reporting, technicians can generate accurate reports on-site, eliminating the need for manual data manipulation and report generation.

- Efficiency and Accuracy: Real-time data input ensures that adjustments are made promptly, improving the overall accuracy of the TAB process.

- Compliance and Standardization: These platforms provide standardized reports following guidelines like NEBB TAB, ensuring compliance and consistency in reporting.

Automate your TAB-work with software

Automate your TAB-work with software

It is crucial for TAB technicians to have the right tools to perform their work. Besides the correct instruments, a dedicated software system to manage all the data is essential.

CxPlanner has been at the forefront of the digital transformation of TAB. By adopting CxPlanner, HVAC professionals can significantly streamline their TAB workflow. The platform's inline TAB spreadsheets simplify data input for various parameters, including voltage, amperage, model, and type.

Modernizing your TAB workflow is not just a convenience, it's a necessity. The HVAC industry is evolving, and staying ahead means adopting efficient and accurate methods. With CxPlanner, you can meet the main challenges of TAB head-on and perform site-based TAB with confidence and precision.

The Cx Agent's Role in TAB

The Cx Agent's Role in TAB

As a Commissioning Agent, your role is pivotal in the commissioning process, which is an essential step in the construction and operation of HVAC systems. Commissioning ensures that all HVAC components are installed, tested, and operated according to the design intent - and according to guidelines like ASHREA Guideline 0.

Working with a software platform not only simplifies the TAB process but also assists Commissioning Agents in their role. It enables them to document and track the TAB results as part of the broader commissioning process, ensuring that the HVAC systems meet the specified performance criteria and energy efficiency standards.

Embrace the digital transformation of the TAB and commissioning processes with CxPlanner, and you'll ensure that your projects are not only efficient but also compliant with industry standards. Cx goes hand in hand with TAB to guarantee that the systems function optimally.

Different kind of balancing in HVAC systems

Different kind of balancing in HVAC systems

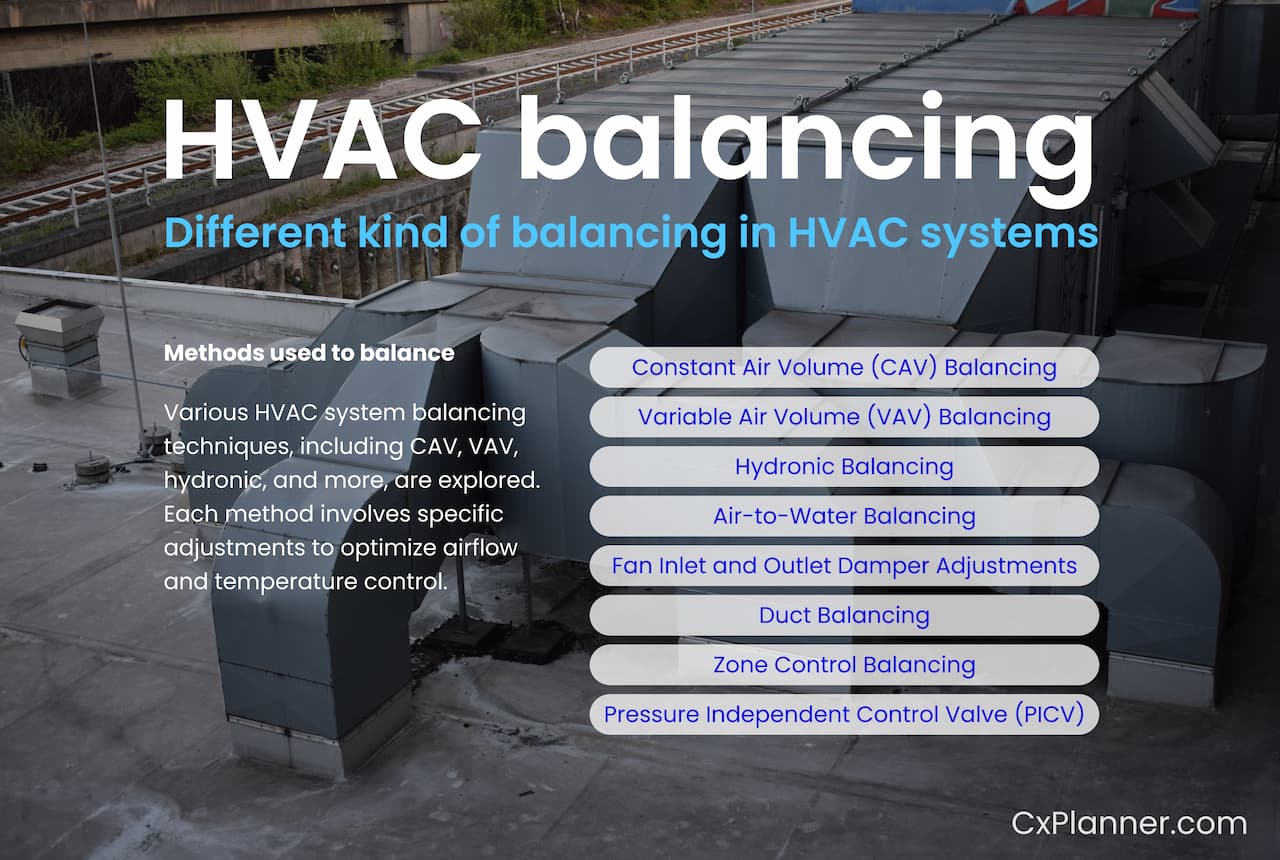

Various HVAC system balancing techniques, including CAV, VAV, hydronic, and more, are explored. Each method involves specific adjustments to optimize airflow and temperature control.

Constant Air Volume (CAV) Balancing:

In CAV systems, airflow remains constant while the temperature varies. Balancing CAV systems involves adjusting dampers, valves, or fan speeds to achieve the desired airflow rate and to ensure temperature control within the specified range.

Variable Air Volume (VAV) Balancing:

VAV systems vary airflow to meet changing heating and cooling loads. Balancing VAV systems includes setting the correct static pressure setpoint, adjusting terminal units (e.g., VAV boxes), and controlling the fan speed to maintain the desired airflow and temperature conditions.

Hydronic Balancing:

Hydronic systems use water for heating or cooling. Balancing hydronic systems involves adjusting control valves, pump speeds, and pipe configurations to distribute the right amount of heated or chilled water to various zones or equipment.

Air-to-Water Balancing:

Systems that transfer heat between air and water require careful balancing. Technicians balance these systems by adjusting heat exchangers, control valves, and pumps to ensure efficient heat transfer and temperature control.

Fan Inlet and Outlet Damper Adjustments:

For systems with fans, technicians adjust inlet and outlet dampers to control airflow rates. Properly set dampers help regulate airflow and static pressure, which is crucial for system efficiency and comfort.

Duct Balancing:

In air distribution systems, balancing ducts involves adjusting dampers and registers to ensure even airflow to all zones or rooms. Technicians measure and adjust airflow in different branches of the ductwork to achieve the specified design airflow.

Zone Control Balancing:

Balancing at the zone level involves adjusting terminal units (e.g., VAV boxes, diffusers) within specific areas or zones. Technicians ensure that each zone receives the appropriate airflow and temperature control to meet occupant comfort requirements.

Pressure Independent Control Valve (PICV) Balancing:

PICVs maintain a constant flow rate regardless of variations in pressure. Balancing PICVs involves setting the desired flow rates for each valve and adjusting the control parameters to maintain constant flow under changing conditions.

Static Pressure Balancing:

Technicians measure and adjust the static pressure in ducts to ensure it matches the design specifications. Proper static pressure balancing is essential for controlling airflow and avoiding issues like excessive noise and energy wastage.

Chilled Beam Balancing:

Chilled beams are often used for cooling in commercial buildings. Technicians adjust the flow of chilled water and the primary air supply to balance the system and maintain comfort conditions in the space.

Tools used for TAB-works

Tools used for TAB-works

Anemometer:

Purpose: Measures airflow velocity and volume, helping to ensure that air is distributed evenly throughout the system.

Manometer:

Purpose: Measures pressure differentials, including static pressure, velocity pressure, and total pressure, which are essential for balancing air and water systems.

Thermometer:

Purpose: Measures temperature at various points in the HVAC system to ensure that heating and cooling requirements are met.

Hygrometer/Psychrometer:

Purpose: Measures humidity levels in the air, which is crucial for maintaining indoor air quality and occupant comfort.

Tachometer:

Purpose: Measures the rotational speed of fans, pumps, and other equipment to ensure they are operating at the specified RPM for proper airflow.

Differential Pressure Gauge:

Purpose: Measures the difference in pressure across filters, coils, and other components to assess their cleanliness and performance.

Pressure Transducer:

Purpose: Converts pressure readings into electrical signals for monitoring and control purposes.

Flow Hood/Balancing Hood:

Purpose: Measures and balances air supply and return in ventilation systems, helping to optimize airflow distribution.

Vane Anemometer:

Purpose: Measures airflow velocity in ducts and at supply and return registers, assisting in airflow adjustments.

Pitot Tube:

Purpose: Measures velocity pressure in ducts and is used to calculate airflow rates and assess air distribution.

Airflow Capture Hood:

Purpose: Measures air volume at supply and return grilles, helping to ensure that air distribution is balanced and meets design specifications.

Rotating Vane Anemometer:

Purpose: Measures airflow velocity and direction in ducts, assisting with airflow adjustments and balancing.

Sound Level Meter:

Purpose: Measures sound levels to assess and mitigate noise issues within the HVAC system, ensuring a comfortable environment for occupants.

Hydronic Flowmeter:

Purpose: Measures the flow rate of water in hydronic systems, aiding in the balancing and performance optimization of these systems.

Ultrasonic Flowmeter:

Purpose: Measures fluid flow, particularly in hydronic systems, using ultrasonic technology to provide non-invasive measurements.

Datalogger:

Purpose: Records and stores data from various instruments over time, facilitating trend analysis and documentation of TAB work.

Pressure Independent Control Valve (PICV):

Purpose: Actuates control valves based on system requirements, maintaining constant flow rates regardless of variations in pressure.