Introduction

Introduction

Commissioning is an added expense that some project owners might prefer to skip. After all, it does add to the project's bottom line. And we won't even argue that point.

But we will argue that the Cx process does lead to better projects, better performance, and improved overall operating costs for a project long-term. But, does it make sense financially? What would a cost-benefit analysis say? You're about to find out.

Is Commissioning Worth It?

Is Commissioning Worth It?

Yes, it is. But there's more to the story, as several studies and experts in the field have noted.

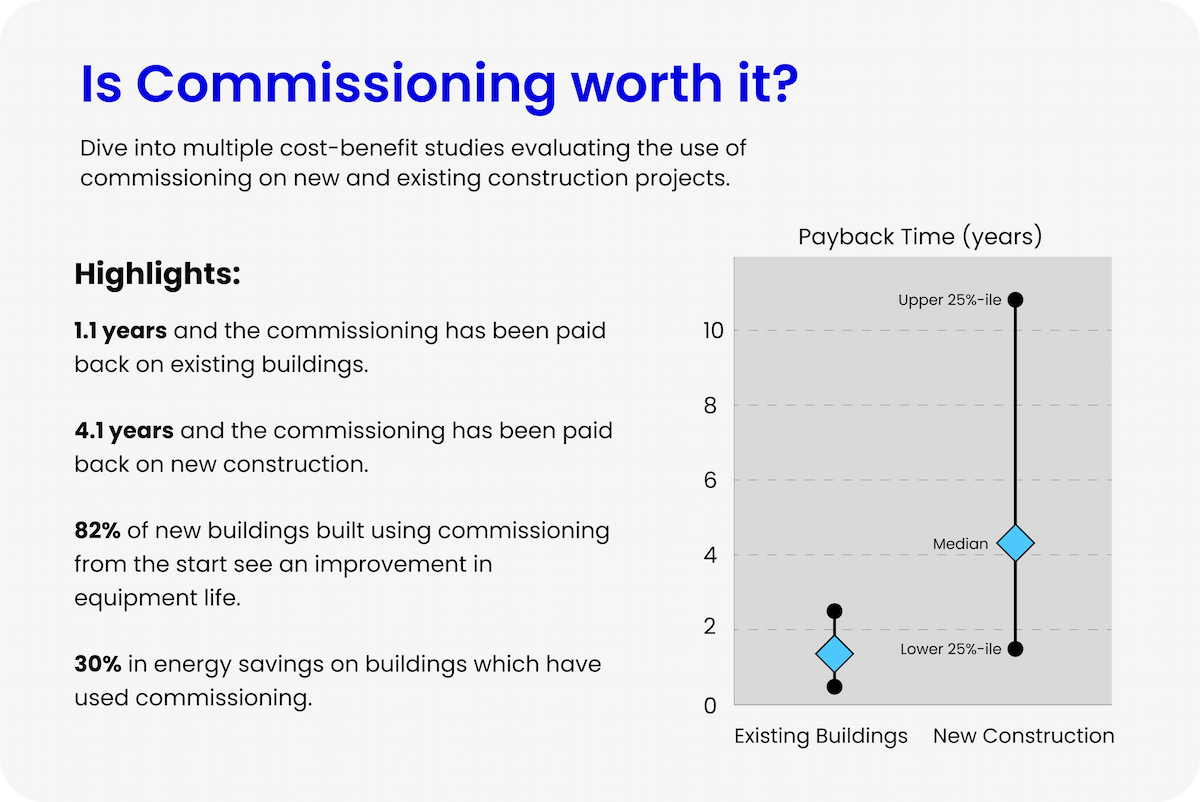

Commissioning can be a large expense and the common concern is that project owners won't recoup their investment, or that the amount of time it takes to recoup is too long. And if we were to only look at these two factors, here's what you'd find:

- According to a 2009 study performed by E. Mills, the average time for a commissioning project to pay back the required investments is 4.1 years for new construction projects.

- The same study showed the payback timeline for existing construction projects is reduced to 1.1 years.

So based on the timeline alone, the Cx process pays for itself in 1 to 4 years. But after that point, it will continue to reward the project owner by saving money each month. It's not as long-term an investment as many people think. There are also other non-capital benefits that will also be seen, such as improved IEQ.

How Does Commissioning Pay for Itself?

How Does Commissioning Pay for Itself?

There are several ways that commissioning pays for itself. The goal is for the Cx process to lead to better project outcomes with fewer mistakes, avoiding the costly setbacks that plague project owner's pockets and construction companies' bottom lines. Here is how it does that.

Energy Savings

One of the most significant benefits that buildings built or renovated using the Cx process realize is energy savings. Through the commissioning process, building envelopes and equipment are tested to ensure they're running as efficiently as possible. This ensures that equipment is sized correctly and uses the optimal amount of energy required to achieve the desired climate in the building.

Without the commissioning process checking on these systems, they could be running inefficiently and using too much energy unnecessarily, even if they appear to be working properly. In fact, the study mentioned earlier by E. Mills showed that 25% of buildings save over 30% on energy costs.

Equipment Lifespan

Properly running equipment verified during the Cx process will also save the building owner money over the long term. The process ensures that every safety device, valve, switch, and software program associated with a piece of equipment is working at handover, providing the customer with peace of mind that their machine is in top form.

Studies have shown that 82% of new buildings built using commissioning from the start see an improvement in equipment life. Just under 60% of renovated buildings also see an increase in equipment life. Much of this has to do with the improved O&M manuals constructed during the project, helping building personnel learn how to operate and maintain their equipment properly.

On-Time Delivery

Roughly 10% of new construction projects built with Cx from the start are occupied on time. The Cx team can find mistakes, errors, or faults earlier in the process, allowing more time for the construction team to fix them. This results in fewer delays and allows project owners to occupy their buildings sooner.

On-time occupation has several benefits. For one, project owners can rent their spaces sooner or avoid high-interest credit payments. Also, if the project owner is renting property while the building is constructed, they'll be able to save those rent payments.

Costly Errors

As the Cx team pays attention to every small aspect of the project, its members are able to find mistakes in design and installation before they become costly endeavors. The amount it costs to repair a mistake found on paper before the system is installed is minimal compared to the cost of disassembling and reconstructing an entire system and all of its components.

It's also worth considering the labor costs and materials costs associated with a mistake. The Cx process allows construction companies to minimize these costs, helping the process pay for itself.

Cost Effectiveness of Commercial Building Commissioning (2018)

Cost Effectiveness of Commercial Building Commissioning (2018)

In 2018 Building Commissioning Association and Lawrence Berkeley National Laboratory revisited E. Mills meta-analysis from 2009 and created an additional analysis based on these data for commercial building commissioning.

As seen in the table below the results from 2009 and 2018 have been compared, and we are seeing an increase in the number and sizes of construction projects included.

| New Construction | 2009 study | 2018 study |

|---|---|---|

| Buildings | 82 | 101 |

| Projects (w/cost data) | 74 | 67 |

| Floor Area (SF) | 8,813,925 | 22,217,059 |

| Construction Cost | $2.2B | $10.1B |

| States incl. | 10 | 18 |

| Existing Buildings | 2009 study | 2018 study |

|---|---|---|

| Buildings | 562 | 738 |

| Projects (w/energy) | 300 | 604 |

| Floor Area (SF) | 90,410,884 | 274,159,847 |

| States incl. | 21 | 18 |

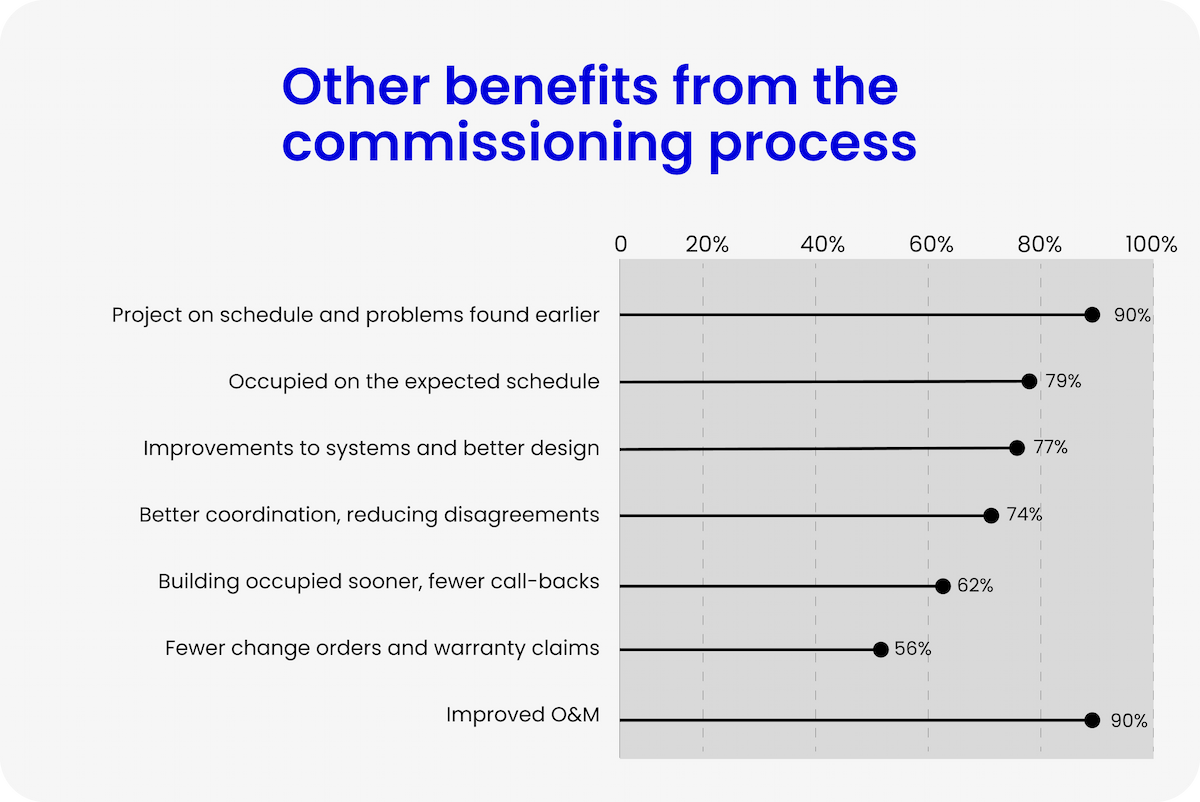

The analysis is based, among other things, on a survey where respondents were asked to describe their motivations for using Commissioning and how Commissioning has contributed value to them.

The statistical extraction shows that in addition to the energy benefits, many different benefits are experienced. The illustration below shows the various advantages - particularly compliance with the project schedule and improved indoor climate.

Meta-analysis of Commissioning projects in the USA (E. Mills 2009)

Meta-analysis of Commissioning projects in the USA (E. Mills 2009)

E. Mills has published two American studies (2004 and 2009), with the 2009 study being particularly large and comprehensive ("Building Commissioning, A Golden Opportunity for Reducing Energy Costs and Greenhouse Gas Emissions"), containing cost-benefit analysis and payback analyses.

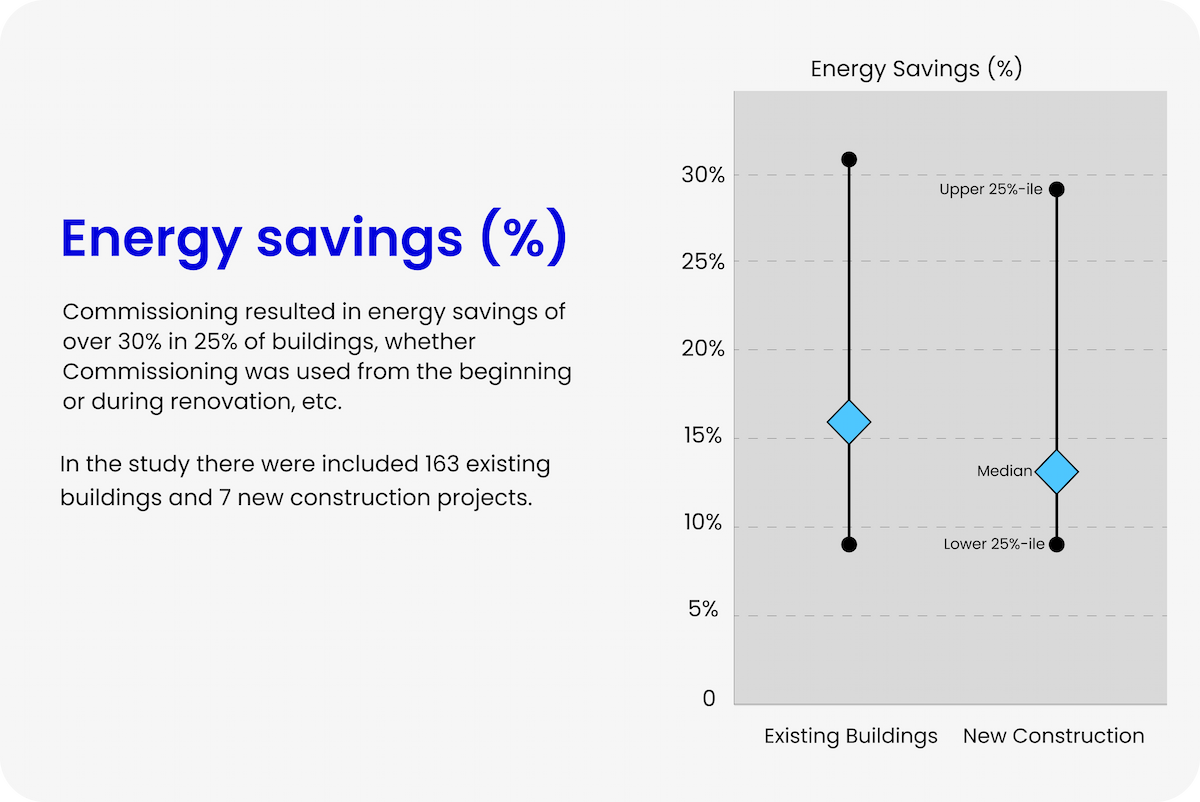

The study includes a meta-analysis consisting of 409 Commissioning projects, covering 82 new constructions and 561 existing buildings.

The study is based on data from over 600 buildings, of which valid comparison data for energy consumption are available for 170 of the buildings.

Among these, 7 new constructions have utilized Commissioning right from the initial phase. The remaining 163 buildings have been evaluated in connection with the use of Commissioning during renovation and improvement.

Energy savings

In the illustration, the median value for energy savings for the 7 new constructions is seen to be 13%.

Renovation and improvement of the existing buildings resulted in an improvement of 16% compared to the previous energy consumption.

Commissioning resulted in energy savings of over 30% in 25% of buildings, whether Commissioning was used from the beginning or during renovation, etc. The illustration shows the energy savings in % and is sourced from E. Mills.

Types of Cost-Benefit Analysis

Types of Cost-Benefit Analysis

Unfortunately, there isn't a specific formula used to calculate the cost-benefit of commissioning, but there are a few methods that can be used.

The first method is the Calculation of Observation method. This method requires focusing on a single observation (an error or mistake) found by the Cx team and then corrected. This method requires calculating the time, direct and indirect costs of fixing the issue, direct cost and indirect costs associated with not fixing the issue, and determining whether the cost of the Cx was worth it.

The other method is the Resource Hours Saved method. In this method, the Cx process catches an issue before the test, saving money on testing and re-testing. This requires fewer test participants, helping project owners spend less. Each test's hours can be calculated and compared to the cost of Cx, which almost always results in savings.

So is Cx Worth It?

So is Cx Worth It?

Cx is absolutely worth it. Commissioning allows project owners and contractors to build better projects in less time, and these finished products use less energy with longer-lasting systems. While it can be hard to calculate the exact amount saved, Cx is an investment that's always worth the price paid.